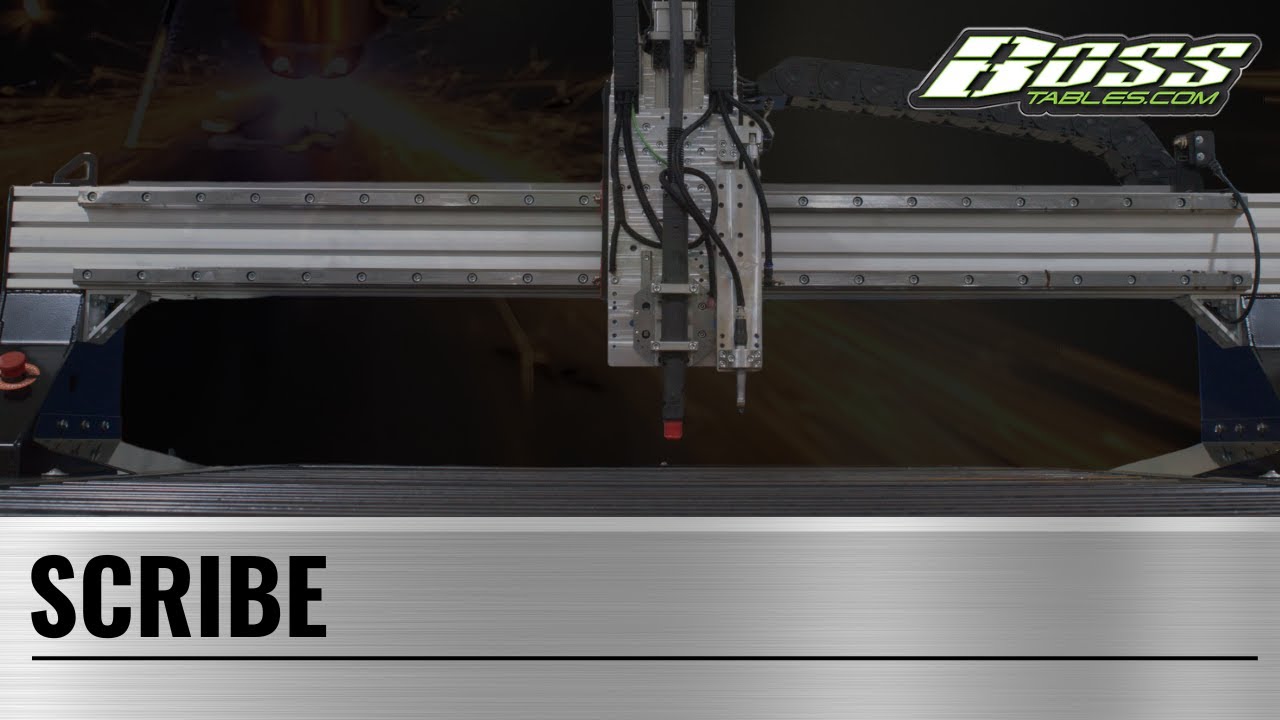

Scribe Accessory: What It Can Do for You.

A scribe accessory on a CNC plasma table is a tool used for marking or engraving on materials without cutting through them. This process creates shallow markings on the surface. In this article, we’ll discuss how it works and its applications, particularly focusing on scenarios where a pneumatic air scribe is utilized.

How does a scribe work?

A pneumatic air scribe operates by using compressed air to create controlled vibrations, which drive its hardened steel tip for engraving or marking tasks on various materials, including metal sheets.

Marking and Labeling:

With the scribe, it allows for a precise marking of parts and pieces on a precise location of the material. Moreover, this is especially useful for labeling components or indicating where operations such as drilling or welding should take place.

Part Identification:

Scribing also serves to incorporate numbers, serial numbers, or other identifying information onto parts being cut. Additionally, this can really help to organize and track components during the manufacturing or fabrication process.

Alignment Parts:

With scribing, it can create alignment marks or reference points on the material. This is helpful when assembling multiple pieces. Therefore, ensures there is an accurate alignment during the assembly process.

Quality Control:

The scribe can be used to add inspection marks or symbols to indicate areas that require additional quality control measures. Therefore, this is quite common in industries where precision and accuracy are important.

Preventing Cut Errors:

In some cases, a scribe line may be used to create a perimeter around a part that is going to be cut. This helps prevent errors by providing a visual guide for the operator and showing that the correct geometry is maintained.

Scoring for Bending or Folding:

When working with materials that need to be bent or folded after cutting, a scribe line can serve as the guide on where to bend. This helps achieve accurate bends.

Adding a scribe to a CNC plasma table enhances versatility and allows to perform tasks beyond cutting. It is a cost-effective way to mark, label, and prepare materials for further processing while maintaining the precision and automation capabilities of the CNC system. Furthermore, this approach ensures efficient production workflows and consistent quality standards. If you have any more questions or want more information, give us a call. Boss Tables: 563-380-1535.